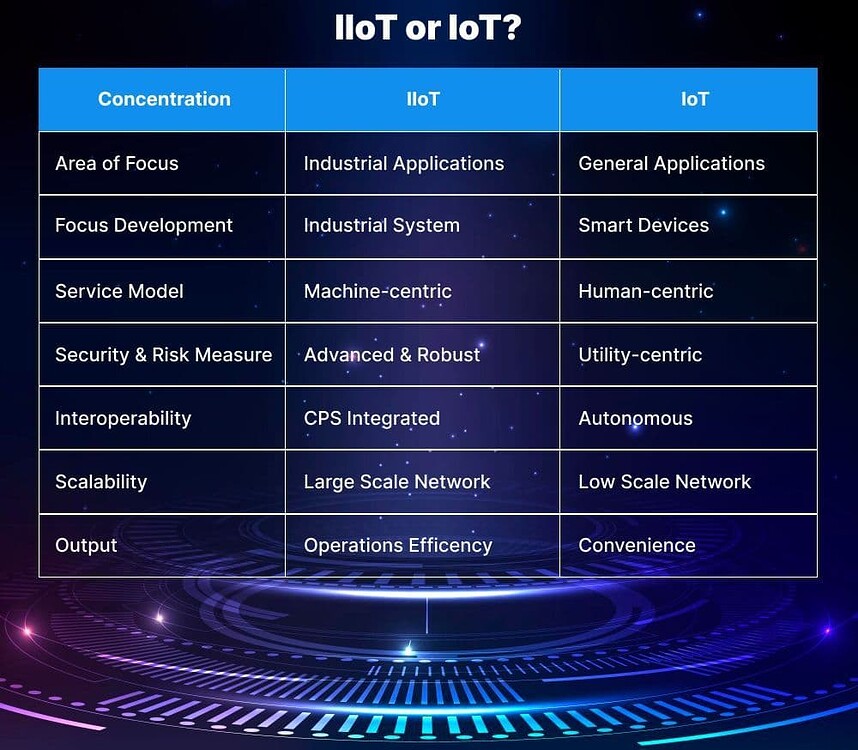

Although some of its main characteristics were already noted in the article on the industrial Internet of Things or IIoT, it is advisable to define more clearly what this technology consists of. Thus, the IIoT is the IoT technology that is applied in industry or agriculture, to name two areas, to improve increases and efficiency, increase the possibilities of scalability, and save the organization time and costs. An example could be the control of processes in critical infrastructures necessary for the functioning of society (for example, the distribution of electrical energy).

The Internet of Things or IoT, on the other hand, is the technology that allows everyday objects (watches, toys, wearables, etc.) to be transformed into digital devices through sensors and actuators capable of transferring data and interrelating without human intervention.

IoT vs IIoT: how are they similar?

Although in some ways the IIoT can be considered a split from the IoT (in fact, they have evolved in parallel and occasionally exchange operating schemes), there is more that separates both technologies than what unites them, as we will see. later.

Apart from the similarity in the name, one of the main shared aspects is that both developments depend on the cloud and an interconnected system.

They also have in common many of the communication protocols and universal standards that allow devices to communicate with each other. Not in vain, most of these “behavioral standards” are built on open source philosophies that facilitate interoperability, in a way that ensures the possibility of using the information obtained for decision-making regardless of who the device manufacturer is.

Likewise, and occasionally, the IoT and IIoT may also share types of sensors used and analytical processing of data. Thus, for example, a sensor to measure humidity can be used in a domestic, industrial, or agricultural setting, providing similar information for all environments that can be used to generate patterns or make more or less complex predictions.

Difference between IOT and IIOT

The truth is that although both technologies depend on the cloud and an interconnected system, they have different characteristics from each other.

Internet of Things (IoT)

Main goal: It is responsible for measuring, collecting, and sending data to a cloud server, through electronic devices and sensors.

Characteristics: It allows communication and cooperation with other devices, to configure them remotely, physically, or via network. It can be used for agriculture, and tracking merchandise shipments, among other things.

Industrial Internet of Things(IIoT)

Main goal: The IIOT optimizes productions and offers maximum efficiency to automatically coordinate multiple sensors. It allows you to control production and obtain statistics in real-time to make better decisions. Predictive maintenance can also be carried out constantly.

Characteristics: Failure analysis or to know maintenance times are achieved with big data; This allows for careful planning and a cost-effective procedure.

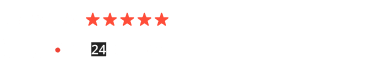

| Aspect | IoT | IIoT |

| Market Focus | Oriented to the general consumer (e.g. personal devices, smart home). | Focused on industrial applications (e.g. manufacturing, logistics). |

| End Devices | Less robust devices, usually for personal or home use. | More robust and technically advanced equipment for industrial use |

| Risk of Failure | The risks of device failure are relatively low. | Failures can have serious consequences in terms of production and safety. |

| Environmental Requirements | They operate primarily in home or office environments. | It must operate reliably under extreme and industrial conditions. |

| Media | They use the Internet, with less emphasis on robust networks. | It requires more robust and secure networks for large volumes of data and real-time communication. |

Why does IoT in the industry have a promising future?

These are just some of the many functionalities offered by the Industrial Internet of Things. The forecasts for its growth, not only technological but also economic, are impressive.

IDC Research reported that the top 3 industries investing in IIoT in 2018 were manufacturing, with a focus on asset management, transportation, with a focus on cargo monitoring and fleet management, and utilities, with a focus on intelligent networks.

Accenture expects IIoT to add $14.2 trillion to the economy, growing at a compound annual growth rate of 7.3% through 2030.

The future of IoT and IIoT

In the coming years, the adoption of IoT and IIoT technologies will continue to grow. The world is expected to have 25 billion connected devices by 2021. Globally, the IIoT market is expected to grow to $771.72 billion by 2026.

These technologies are already having an impact on a wide range of sectors, from consumer goods to manufacturing to healthcare, and will continue to drive digital transformation and significantly change almost all sectors along with other technologies in Industry 4.0. When used in combination with automation, data analytics, artificial intelligence, and other advanced technologies, IoT and IIoT have the potential to create even more impact.

Today, IoT and IIoT can help provide companies with advantages over the competition. Companies increasingly need these technologies to avoid falling behind their competitors, and their importance in business will continue to grow in the coming years. These technologies will also become increasingly common in consumers’ lives. As the future becomes more connected, digitized, and intelligent, IoT and IIoT are playing an increasingly important role in our professional and personal lives.

Also read: IoT In Smart Parking Management: Benefits & Challenges

What separates IIoT from IoT?

To highlight the differences between IIoT and IoT, this section will be broken down into different sections, based on the scheme proposed in the article IIoT vs. Industrial IoT: 10 Differences That Matter and completing it with additional content along with the usage of Parangat Technologies.

Objective and scope of application

The RTI company pointed out this difference clearly through the following statement:

The IoT and IIoT have two separate areas of interest. Industrial IoT connects critical machines and sensors in high-risk activities such as aerospace, defense, healthcare, and energy. These are systems in which failures often result in life-threatening or other emergencies. On the other hand, IoT systems tend to be consumer-level devices, such as wearable fitness tools, smart home thermometers, and automatic pet feeders. “They are important and convenient, but breakdowns do not immediately create emergencies.”

That is, the main objective of the so-called “consumer” IoT is to offer a better user experience based on connectivity to ensure personal comfort or control consumption of domestic supplies (water, energy, etc.).

The IIoT, on the other hand, seeks to obtain maximum efficiency in any industrial plant or network through multiple sensors that interact in a coordinated and automatic manner. The information collected is served at a checkpoint or fed to a twin device, also known as a digital twin.

Security

The security of IoT devices is an issue of increasing concern. It constitutes one of the main barriers to entry for an even broader adoption of these technologies. However, a security breach in an IIoT system has much more serious consequences than in a home or personal IoT application.

Therefore, the security measures adopted in both cases are different, being much more robust in the case of the industrial Internet of Things (special chipsets, encryption and authentication, etc.).

Interoperability

One of the main challenges facing the IIoT is the need to integrate legacy systems that operate under other protocols or technologies since companies cannot invest in machinery at the same pace as new developments that come to market.

The IIoT, unlike the IoT, must therefore show an “umbrella” that supports various protocols and data sets, and its integration with the enterprise resource planning systems or ERPs of companies is also required.

Scalability

Scalability, applied to a technological field, refers to the ability of a system to increase its working capacity without compromising its operation and quality.

Taking this definition to the topic of this article, an IIoT development must be able, even in the future, to add new components and devices without reducing the general performance of the different processes, a quality that is not so relevant in an IoT system.

Precision, Accuracy, and reliability

There is no doubt that precision and accuracy are two key parameters of an IIoT system, especially considering the millions of data that must be processed every second. So, as the IoT for All article referenced above states, in an IIoT environment “close enough” is not enough, and results in a loss of efficiency, downtime, and revenue.

In addition, it is necessary to have a high degree of reliability to the devices and the information they capture, especially considering the environmental conditions (heat, cold, high vibrations, pressure, etc.) in which IIoT systems perform their work.

Latency and redundancy

Latency is understood as the time it takes for a computer or device to execute an action from the moment the order to do so is activated. Redundancy, on the other hand, refers to replicated components or systems of the network that can be used in the event of a system failure to ensure the supply or service.

Both are fundamental concepts in an IIoT system compared to the benefits that a consumer IoT development must offer in this sense.

What makes IIoT the backbone of industry 4.0 transformation?

IIoT stands as a core technology that enables the digitalization of manufacturing under the banner of Industry. 4.0. By providing equipment interconnectivity and data exchange, IIoT powers the hyperconnected, information-driven factory.

Additional Industry 4.0 technologies such as industrial big data analytics, artificial intelligence, digital twin simulations, and cloud-based industrial software platforms integrate directly with IIoT infrastructure and sensors. Together, these innovations enable entirely new capabilities. as:

– Decentralized production decisions: IIoT machinery self-modifies based on operational data rather than centralized control.

– Intelligent supply chain adaptation: Inventory levels change automatically based on real-time order data.

– Rapid design iterations: Digital twin mock testing of new products replaces physical prototyping and testing.

Industry 4.0 indicates that manufacturing companies are increasing IIoT adoption to drive efficiency, expecting 15-30% improvements in labor productivity and 30-50% reductions in machine downtime. But cost optimization tells only part of the story: IIoT also unlocks breakthrough innovations to better serve customers and pivot strategically.

IoT and IIoT solutions from Parangat Technologies

To take advantage of the full capabilities of IoT and IIoT technology, you will need a powerful software platform to help you manage your connected devices and the data they collect. Parangat Technologies offers you an integrated environment that incorporates machine operation, data logging, and Artificial Business intelligence. It includes SCADA systems, HMI, IoT, IIoT, soft PLC, and dynamic production reporting, all on a single platform. Trusted by more than millions of customers and trusted partners worldwide, Parangat Technologies enables Smart Cities and Smart Factories and delivers systems for organizations across a wide variety of industries.

Parangat Technologies offers easy integration with existing systems and easy-to-use wizards and tools. You can quickly configure projects, automate routine commands, and create custom alarms, events, and views. Parangat Technologies’s advanced analytics, reporting, and visualization help you get value from your data, and you can quickly and securely access your information and control your system from anywhere. To learn more about how it can help your organization create a smart factory, building, or city and improve its efficiency, productivity, reliability, and ROI, contact us today.

Conclusion:

The battle of two similar-looking terms is confusing. But the difference is more overwhelming. Although IIoT is a larger system and IoT is more of a piece of the puzzle, the applications of both are correlated. In the era of Big Data and analytics, IIoT is more than just a data exchange system. It has much more to offer than IoT. Therefore, if you are planning a unanimous system that can facilitate the synchronization of the multiple elements of IIOT, you can create larger market opportunities. It’s more like the difference between a private jet and an Airbus jumbo jet!

We look at how you can build robust IIoT systems for any business domain. If you still have questions, feel free to contact us for amazing app-based IIoT solutions.